How To Build And Install Drawers

The discussion "drawer" followed past dados and dovetails is surly enough to scare off many a DIYer. Nonetheless, at that place's an easier style to build a drawer without using a table saw or router, yet results in a beautiful, sturdy assembly but the same. Worried virtually visible fasteners? Our blueprint cleverly hides them out of sight for a truly professional person expect. Follow along to see how you tin apace build whatsoever size drawer using this simple method.

Related Tutorials: How to Install Drawer Slides &Build a Midcentury Nightstand

Price: $half dozen

Time: one ½ hours

Difficulty: Easy. Foursquare cuts and pocket hole joinery make this a comfortable beginner project.

(ane) 1 x 3 x 6 Board to make the drawer front, dorsum and sides

(1) one x six Board to make the drawer front end

(2) 3/8 10 3/viii x 3′ Square Dowel to brand cleats

(1) ¼ inch Plywood to make the drawer base

(eight) ane¼ inch Wood Screws to join the sides

(two) 1 inch Wood Screws to attach the drawer face

¾ inch Finish Nails to attach the cleats

Wood Gum

Wood Filler

Note: This cut list is sized to fit our Midcentury Nightstand

1 x 3 Sides – 2 @ sixteen inches (1″ less than depth of cabinet box)

1 x 3 Front – i @ 18 inches (2½" less than width of cabinet opening)

ane x iii Back – ane @ 18 inches (ii½" less than width of cabinet opening)

three/8 x 3/8 Cleats – two @ eighteen inches (2½" less than width of cabinet opening)

3/8 ten iii/viii Cleats – 2 @ thirteen¾ inches (2¼" less than length 1×iii Sides)

¼ inch Plywood – one @ 18″ x fourteen½" (Length of 1×3 Front end – by – 1½" less than length of Sides)

1 x six Drawer Face – 1 @ 20¼ inches (¼" less than width of opening)

Steps

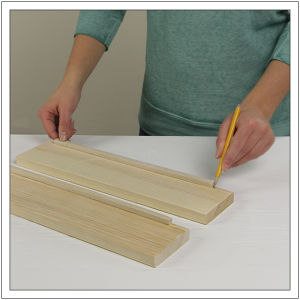

1. Cutting the Parts

Using a miter saw and the cutting listing in a higher place, cut the one×6, i×3, and square dowels to size. Mark cut lines on the face of the plywood using a framing square. Place painter'south record over the cut lines, and and so mark them over again if necessary. The painter's tape volition keep the plywood from splintering during the cutting. Cutting forth the lines using a round saw. Lightly sand the cut edges of all the parts to remove burrs.

TIP: Check out our DIY Cutting Fence Tutorial for straighter cuts without a table saw.

2. Drill the Pocket Holes

2. Drill the Pocket Holes

Place the 1×iii front and back pieces on the work surface. Using a Kreg Jig, drill two pocket holes in each terminate of both boards.

three. Drill the Drawer Face Holes

Place the 1×6 drawer face on the piece of work surface with the pocket holes facing downwards. Using a record measure and a pencil, brand two marks iv inches from the ends of the board, and centered on its width. Using a Drill/Driver, create two pilot holes. These pilot holes will later on be used to attach the drawer face.

4. Add together Cleats to the Front and Back Pieces

Position an 18-inch cleat on the one×3 front and back pieces affluent with their lesser edges and ends. Apply a bead of wood mucilage to the cleat, reposition it, and so boom it in place using a pneumatic smash gun and ¾-inch finish nails.

5. Attach Cleats to the 1×3 Side Pieces

Position the remaining cleats on the 16-inch-long sides flush with their bottom edges and centered on their lengths. This should create a 1 one/8-inch inset on each stop of each cleat. Marking the ends of the cleats with a pencil. Remove the cleats, apply a dewdrop of forest mucilage, and and then put them back in place. Secure the cleats using a pneumatic nail gun and ¾-inch end nails.

6. Dryfit the Sides

Ready the 1×3 pieces upright so that the cleats run along their bottom edge. Apply mucilage to the ends of the forepart and back pieces and then position them between the sides, flush with their ends.

7. Assemble the Sides

In the name of non using fancy tools, I've used a very bones method for belongings the joints square during assembly. Merely place a block (make sure it has a truly foursquare corner) into the corner and clamp information technology tightly to each side. This will help hold the pieces in place while inserting and driving 1¼-inch pocket screws through the pocket holes and into the adjoining side. Once all four corners are assembled, bank check (and recheck) that the assembly is square by using a speed or framing foursquare and measuring corner to corner.

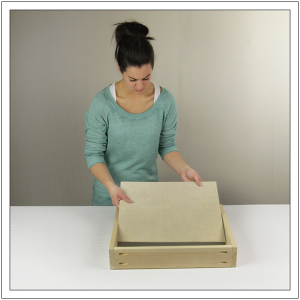

8. Insert the Plywood Base

Utilise a bead of wood glue to the top edge of each cleat. Position the plywood inside the frame on the cleats.

Tip: One time the drawer is painted or stained, I like to run a pocket-sized bead of clear caulk along the edges of the plywood base of operations to keep grit from falling between the plywood and the 1x3s. Additionally, if the drawer will hold heavy objects, consider using ½ inch plywood instead.

9. Attach the Drawer Face

Center the front of the drawer on the 1×6 face up. Depending on your application, allow the drawer face to hang below the drawer box. Mark the placement of the drawer on the ane×6, and then remove the drawer. Utilise wood glue inside the marked expanse, and and then reposition the drawer. Using a drill/commuter, bulldoze 1 inch forest screws through the airplane pilot holes in the drawer front and into the behind of the ane×6 drawer face.

Tip: For a perfect fit, information technology'southward best to fully install the drawer box, and and so position and attach the face.

Tip: Check out our How to Install Drawer Slides tutorial.

More Building PLANS

Source: https://build-basic.com/build-a-basic-diy-drawer/

Posted by: boydafterand.blogspot.com

0 Response to "How To Build And Install Drawers"

Post a Comment